Let’s talk about conveyor systems—those unsung heroes of modern industry that keep the wheels of commerce turning smoothly.

Picture this: You’re at a bustling warehouse, and everything is moving like a well-oiled machine. Imagine if that machine had a little upgrade—something as simple as steel conveyor rollers.

Sounds pretty neat, right? Well, that’s because it is! Let’s dive into how conveyor rollers can supercharge your conveyor system performance and why they might just be the upgrade you’ve been searching for.

Unlocking the Power of Steel Conveyor Rollers

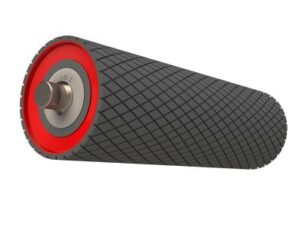

Steel conveyor rollers are the unsung champions of the conveyor world. They’re built to last and easily handle the rough and tumble of daily operations.

But what makes them stand out from the crowd? For starters, steel conveyor rollers offer superior strength and durability compared to their plastic or rubber counterparts.

This means they can handle heavier loads, withstand harsh conditions, and maintain performance over time.

When you invest in steel conveyor rollers, you’re not just buying a component but investing in the efficiency and longevity of your entire conveyor system.

This is why steel conveyor rollers in Australia are often the preferred choice for high-demand environments.

Why Choose Steel Over Other Materials?

It’s a fair question—why not just stick with the old conveyor rollers you’ve got? Well, let’s break it down. Steel conveyor rollers come with a host of benefits:

- Durability: Unlike plastic rollers, steel conveyor rollers can withstand impacts, abrasions, and extreme temperatures. They’re built tough to handle whatever your operations throw at them.

- Load Capacity: Steel conveyor rollers are the go-to for heavy loads. Their robust construction ensures they can support and transport even the heaviest materials without buckling under pressure.

- Longevity: Steel conveyor rollers have a longer lifespan compared to other types. This means fewer replacements and less downtime, saving you money and hassle in the long run.

Where to Find the Best Conveyor Rollers for Sale

So, where can you get your hands on high-quality steel conveyor rollers? Look no further than rollers Australia.

With a reputation for providing top-notch conveyor solutions, rollers Australia offers a wide range of options tailored to meet your specific needs.

Whether you’re searching for conveyor rollers for sale or need a custom solution, rollers Australia has covered you.

Here’s a tip: When shopping for conveyor rollers for sale, check for quality and compatibility with your existing system.

Quality rollers will not only improve performance but also extend the lifespan of your conveyor system.

Upgrading Your System: What to Expect

Switching to steel conveyor rollers can seem like a big step, but it’s a move that pays off. Here’s what you can expect:

- Enhanced Performance: Steel conveyor rollers will make your operation smoother and more reliable. They reduce friction and ensure a more consistent movement of materials.

- Reduced Maintenance: Steel conveyor rollers require less frequent maintenance, thanks to their durability. This means less downtime and fewer disruptions to your workflow.

- Cost Efficiency: While the initial investment might be higher, the long-term savings on repairs and replacements make steel conveyor rollers a cost-effective choice.

Conclusion

Investing in steel conveyor rollers is more than just an upgrade—it’s a strategic move towards enhancing your conveyor system’s performance.

Steel conveyor rollers are a game-changer for any high-demand environment with their unmatched durability, load capacity, and longevity.

So, next time you’re considering an upgrade, consider the benefits of steel conveyor rollers and how they can transform your operations.

For top-quality options, explore Rollers Australia and find the perfect conveyor rollers for sale that meet your needs.

By making the switch, you’re not just improving a component; you’re elevating the entire efficiency of your conveyor system. And isn’t that what we’re all striving for?