Hydraulic oil is a critical component of the hydraulic system and plays a crucial role in ensuring equipment performance. As the Hydraulic Oil For Sale help to ensure that your hydraulic systems are operating at peak efficiency and reduce downtime.

Discuss hydraulic oil filters and how they are effective filters:

Hydraulic Oil Filter

Hydraulic oil filters remove contaminants from the oil. They are a key component of hydraulic systems and can be used for many applications including mining, construction, agriculture and more.

- Hydraulic filters are designed to remove water from hydraulic fluids. Water contamination can cause corrosion in equipment or reduce its life span. A small amount of water mixed with oil is not usually harmful. However, if too much water enters your system it can cause damage.

- Filters should be checked regularly so you know when it’s time to replace them before they fail you unexpectedly.

What is Hydraulic Oil?

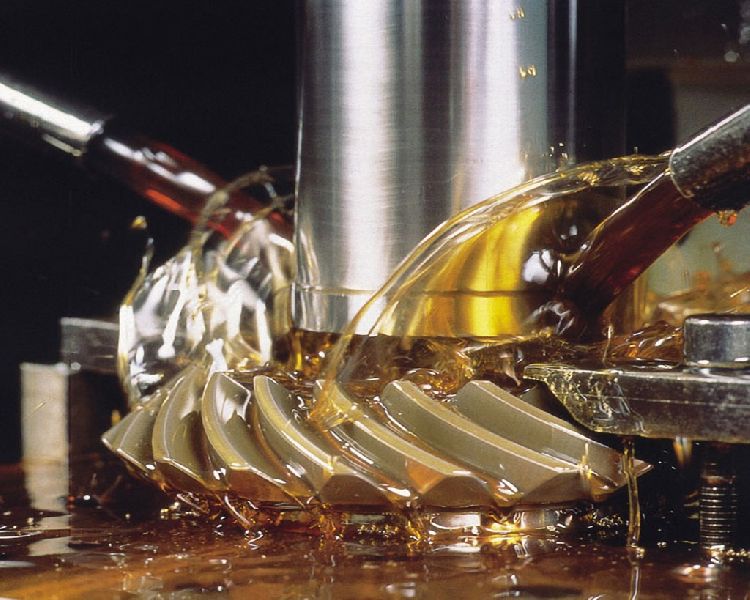

Hydraulic oil is a lubricant used in Hydraulic Power Packs Systems. It can be a liquid or gel, depending on the application. Hydraulic oils are used in vehicles, construction equipment and agricultural machinery.

Because hydraulic oils are used for many different purposes by many different industries, there are several types of hydraulic oil available today. Each type has unique properties that make it suitable for certain applications but not others. Understanding these differences can help you choose the right type of lubricant when you need it most.

There are two basic types of hydraulic oils: synthetic and mineral. Synthetic hydraulic oils are derived from man-made materials, while mineral hydraulic oils are naturally occurring compounds.

Benefits of Using Hydraulic Oil Filter

The benefits of using hydraulic oil filters are many. They can help ensure clean oil is used in equipment, which will prolong the life of the equipment and prevent damage to it. Filters also help prevent damage to the environment by removing contaminants from hydraulic fluid, including water, dirt and rust particles.

Hydraulic fluids are often used in industrial settings where they need to be filtered regularly to remain effective at their job. While keeping your employees safe from harm caused by contaminated fluids leaking out onto floors or machinery during storage periods (or even just regular use).

Filters are also useful for ensuring that hydraulic fluid stays in good condition and does not become contaminated over time, which could cause damage to equipment or even create safety hazards.

How to Choose a Filter?

- Choose a filter that meets your needs.

- Choose a filter that is easy to maintain.

- Choose a filter that has a long life.

- Choose a cost-effective filter.

- Choose a filter that is easy to install and clean, if applicable (for example, some filters are designed for quick change outs).

Some filters are designed for quick change outs, while others are not. Some filters have easy-to-clean designs, while others do not. The type of filter you choose will depend on the size of your pool and the type of filtration system that is currently in place.

Conclusion

The hydraulic oil filters are a critical part of any hydraulic system. It can save you time and money by ensuring clean hydraulic oil, which in turn results in less wear on your equipment. If you have any questions about choosing the right filter for your application or would like more information on how we can help with your next project, please contact us today.