Pallet Strapping or banding is the procedure of using a plastic or metal strap to unitise, palletise or package items together. Strapping is used in a number of sectors from shipping large industrial devices and wood to strengthening cases in e-commerce fulfillment centers. For this reason, there are many qualities and types of materials available in the market.

Strapping is used to secure a package of items either for shipping or saving. Keeping items included helps you to save space, and creates it harder for pieces to get lost in the procedure. If you are shipping numerous boxes, having them secured to each other creates locating the packages easier.

Uses of Strapping

Strapping is usually used in the packaging industry, but it can be used for industrial reasons as well. For example, parts of pipe and stainless-steel beams often take advantage of inspired Metal Strapping both in storage and in shipping.

Types of Strapping Material

With a number of applications and uses, it is important to understand the different types of strapping materials. Materials used come in multiple strength levels as well as elongation and recovery rates.

-

Steel Strapping

Steel Strapping is the earliest and most generally used banding components to this day. This is perfect for extreme tasks that require a huge or very heavy-duty strap. This strapping is maximum for packaging industrial devices, large construction components, and shipping metal coils.

-

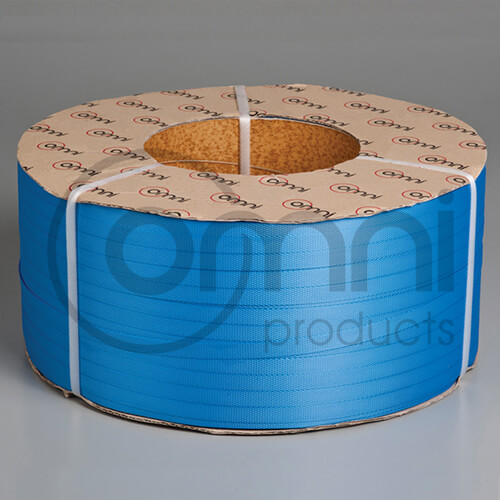

Plastic Strapping

Plastic strapping components are designed from cotton, polypropylene and are available in a number of strong points, styles, and completes. Compared with Metal Strapping, elongation and restoration are a key factor in deciding which kind of plastic strap to use.

-

Polyester Strapping

Polyester strapping is the most generally used plastic strapping content. Its strength and sturdiness are making it the most generally used content to substitute Metal Strapping.

The advanced level of elongation and recovery create a cotton strapping ideal for packaging loads that are vulnerable to moving. The elongation provided by the cotton strap helps to reduce the effect of unexpected changes in strength. As the burden changes, the ties stretch out reducing the force of a sudden shift. The straps recovery capabilities then pull the burden back into the original position.

-

Polypropylene Strapping

Polypropylene strapping or PET Strapping is a cost-effective strapping material compared to many other components. It’s designed for light to medium responsibility unitising, palletising and combining. Consistent pressure to polypropylene strapping can result in the unrecoverable dead stretch and lack of ability to return to its unique length.

Once you have determined which kind of Pallet Strapping you will use, you may need specific resources like a tensioner, sealant, and cutter machine in order to pack and unpack the deliveries. The size of the resources you will need will match the size of the strapping you have decided to use, so do not get your resources before identifying which strapping is going to work best for you. Once that is done, then you can obtain the resources.

Conclusion:

So really all you need to compare is the types of material for Pallet Strapping and how they will best fit your needs based on the product type and weight.

Source: Uses and need of Strapping: Know the strapping material