In a world where sustainability has taken centre stage, innovation is stepping up to the plate, and one technology that’s shining brightly on the eco-friendly stage is 3D printing. While 3D printing is often associated with creating intricate designs and prototypes, its potential for promoting sustainable practices is a game-changer.

From reducing waste to revolutionising manufacturing processes, let’s explore the remarkable ways in which 3D printing is driving sustainable solutions.

Less Waste, More Efficiency

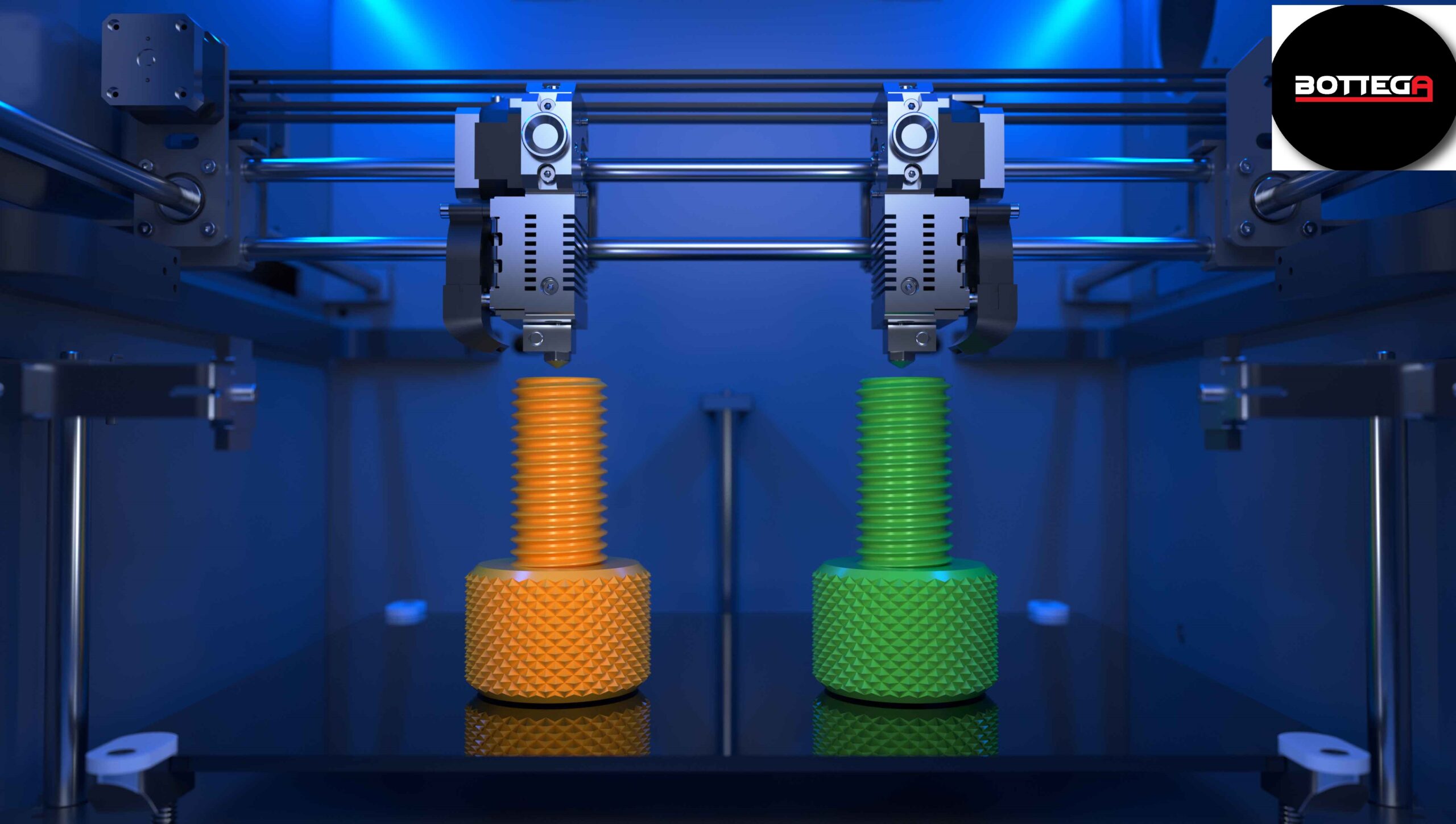

Traditional manufacturing methods often involve subtractive processes where excess material is removed to shape the final product. This results in significant waste, which isn’t just environmentally unfriendly, but also costly. 3D printing services, on the other hand, is an additive process where the material is deposited layer by layer to create the desired object. This approach minimises waste by using only the necessary amount of material, making it a greener alternative to traditional manufacturing.

Localised Production and Reduced Carbon Footprint

One of the unique aspects of 3D printing is its ability to enable localised production. Instead of shipping products across vast distances, 3D printers can be placed closer to the point of need, reducing transportation-related emissions. This localised approach not only cuts down on carbon footprint but also contributes to a more sustainable and efficient supply chain.

Recycling Reinvented

3D printing has the potential to revolutionise recycling efforts. It allows for the repurposing of materials, such as using recycled plastics or metals as feedstock for printing new objects. This closed-loop approach minimises the demand for new raw materials and reduces the strain on the environment. Imagine a future where discarded plastic is transformed into useful products through the magic of 3D printing.

Customisation for Efficiency

Personalisation doesn’t just enhance user experience; it can also contribute to sustainability. With 3D printing, customisation becomes easier and more accessible. This means products can be tailored to exact specifications, reducing the need for excess materials and energy. Whether it’s a customised medical implant or a precisely fitting mechanical part, 3D printing ensures that resources are utilised efficiently.

Revolutionising Architecture and Construction

The construction industry is embracing the potential of 3D printing to create sustainable structures. Additive manufacturing can produce intricate designs and shapes that would be challenging to achieve through traditional methods. This leads to resource-efficient designs, reduced construction waste, and even the possibility of using eco-friendly materials like recycled concrete.

Empowering Local Economies

3D printing can empower local communities by enabling small-scale production and entrepreneurship. Local artisans and businesses can harness the technology to create products on demand, reducing the need for large-scale, resource-intensive manufacturing processes. This localised approach not only supports local economies but also fosters sustainable practices.

Conclusion

In conclusion, 3D printing isn’t just a technological marvel; it’s a catalyst for sustainable change. By minimising waste, enabling localised production, and revolutionising industries, 3D printing is paving the way for a more eco-friendly future. As we embrace this innovative technology, we’re not just creating objects; we’re shaping a world where sustainable solutions are at the forefront of design and manufacturing. So, let’s celebrate the union of technology and sustainability as 3D printing takes centre stage in building a greener and more responsible tomorrow.