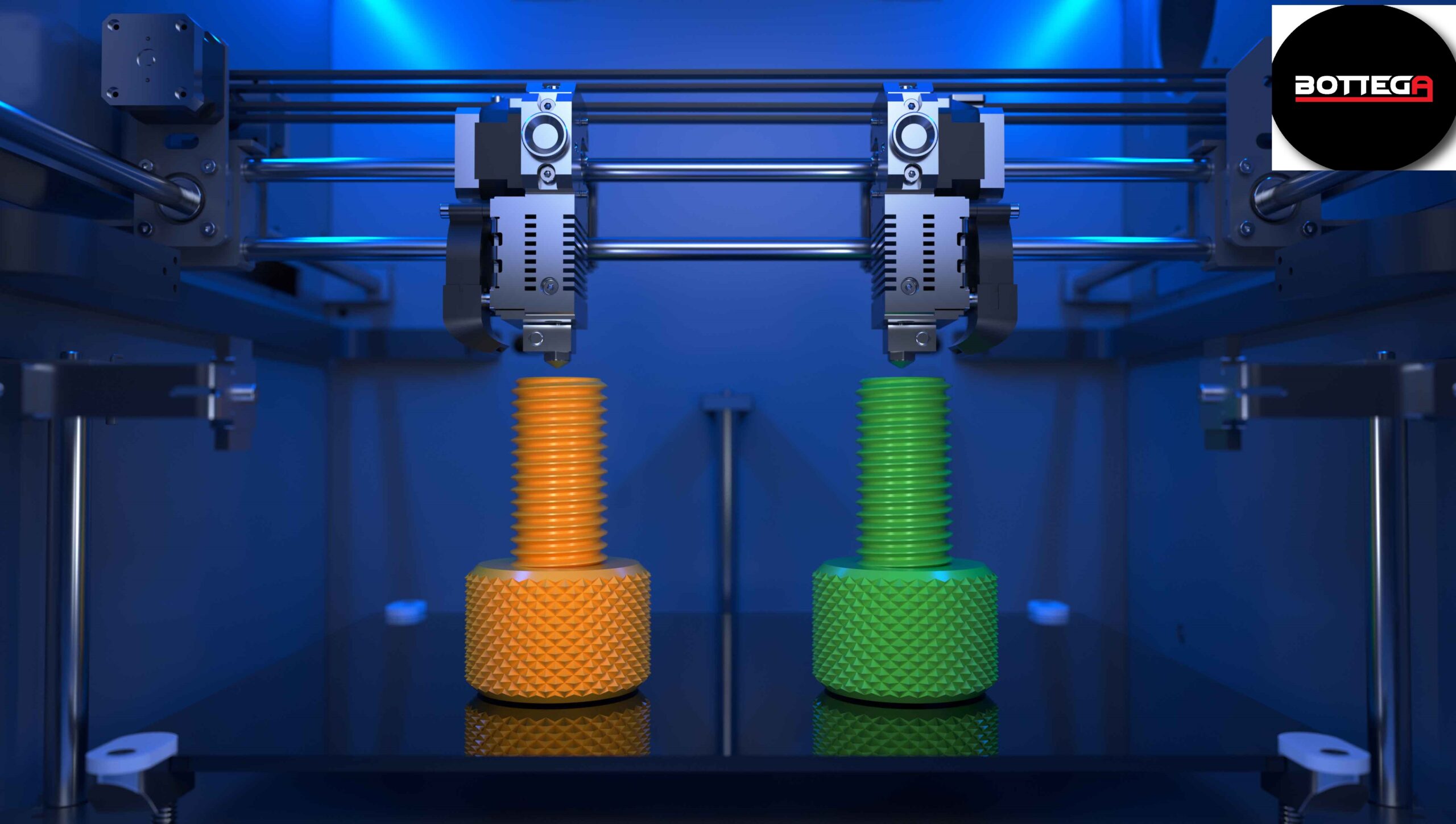

3D printing has revolutionized the way we make things. It’s an incredible technology that is changing the world, but it’s also a tool that can help you save time and money in your workday. Here are some tips on how to get the most out of 3D Printing Business :

Design for 3D printing

Designing your product to be 3D printed is a great way to streamline the design process, reduce costs and get a product out faster. However, it’s important that you design with strength and durability in mind so that your product can withstand the rigors of everyday use.

In addition, because there are many different types of printers available (some designed specifically for industrial applications), it’s also essential that you consider aesthetic factors when designing for 3D printing. If you’re new to designing products with this technology in mind–or if you already have some experience but want some tips on how best to approach things–here are some strategies:

When designing objects meant for everyday use such as kitchen appliances or tools like hammers and wrenches, make sure they’re strong enough not only during assembly but also after years of repeated use by consumers who may abuse them (e.g., dropping them). Consider using reinforced materials such as steel rods instead of plastic ones if possible since steel has higher tensile strength than most plastics used today.

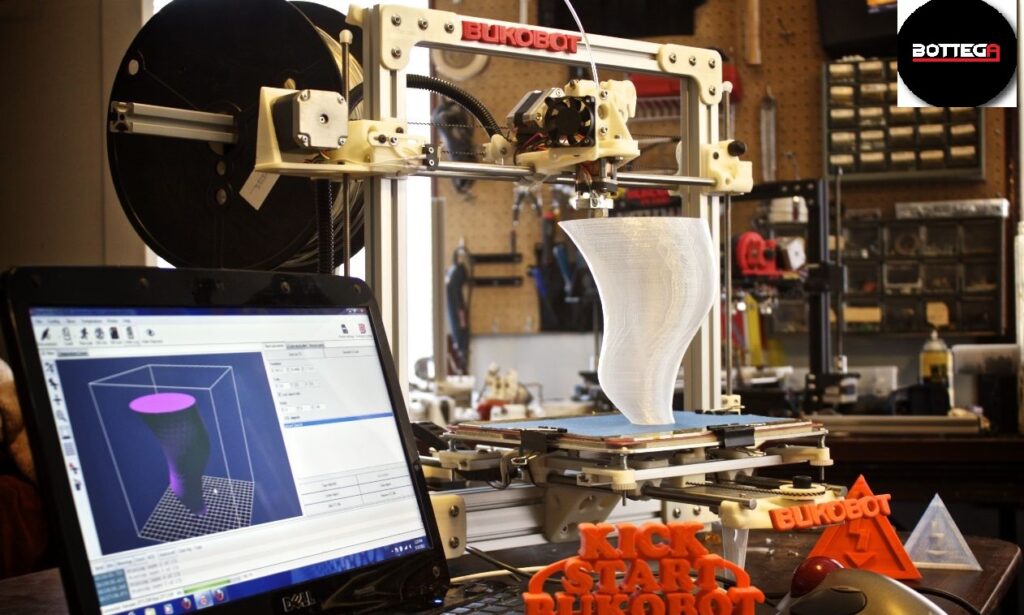

Prototype quickly and affordably

When it comes to prototyping, there are tons of options available. The most common materials used for 3D printing are plastic and metal. While both have their advantages, you’ll want to choose the right material for your prototype based on its purpose and the end result you’re trying to achieve.

If you need something that’s lightweight but strong enough for real-world use (say, if someone were going to be wearing it), metal is probably your best bet. However, if this isn’t required by your design or function then there are several other options worth considering:

- Acrylics–Acrylics can be made translucent so that light passes through them without being distorted; this makes them ideal for lenses or other optical applications where clarity is important

- Carbon fiber composites–Carbon fibers are extremely strong and stiff compared with steel or aluminum alloys; they’re also much lighter than those metals!

Use support materials appropriately

Support materials are not always needed, but when they are, it’s important to use them appropriately.

Firstly, you must determine if your design requires support material. If you’re creating an object with overhanging features or sharp angles that might be difficult for the printer to handle, then support structures are likely necessary. However, if you’re Printing something that doesn’t have any complex shapes and can easily be printed without additional measures taken (such as cubes), then there’s no need for any extra materials at all!

The benefits of using support material include:

- Improved print quality

- Increased stability during printing

Conclusion

We are excited to see the future of 3D printing business and what it holds for us. We hope this article has given you some ideas on how to get started with 3D printing in your business.